Why That Skinny Handrail Won't Be There When You Need It

Last week, I got a call from a guy who'd installed his own deck railing two years ago. Used a kit from one of the big box stores—saved himself about $600. Now the whole thing wobbled like a loose tooth, and his wife refused to use the deck stairs anymore. "I followed the instructions exactly," he told me. He did. The problem wasn't installation. It was that the railing was built from steel tubing you could practically dent with your thumb.

The Grab Test Nobody Thinks About

Here's what I tell people: a handrail has three jobs. It needs to look good—because it's a visible part of your home. It needs to meet code—because that's the bare minimum for safety. And most importantly, it needs to be there—solid and reliable—the one time you actually need to grab it.

You know when that is? When you're off balance. When you're carrying something awkward down the stairs. When it's dark, or icy, or you just misjudged that last step. In that split second, you're not gently resting your hand on the rail. You're grabbing it hard, putting your full body weight on it, trusting it completely.

That's when thickness matters.

What "Gauge" Actually Means

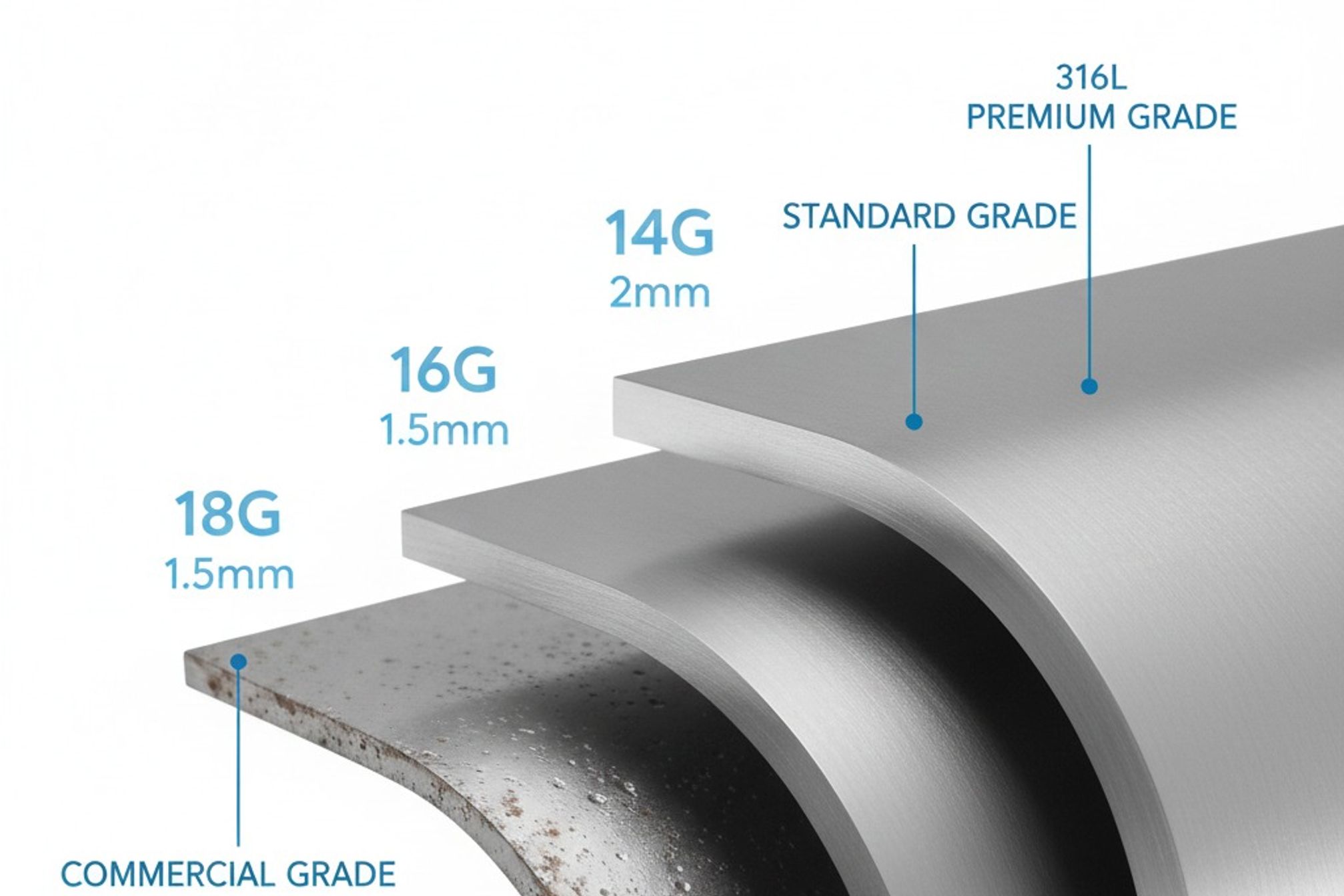

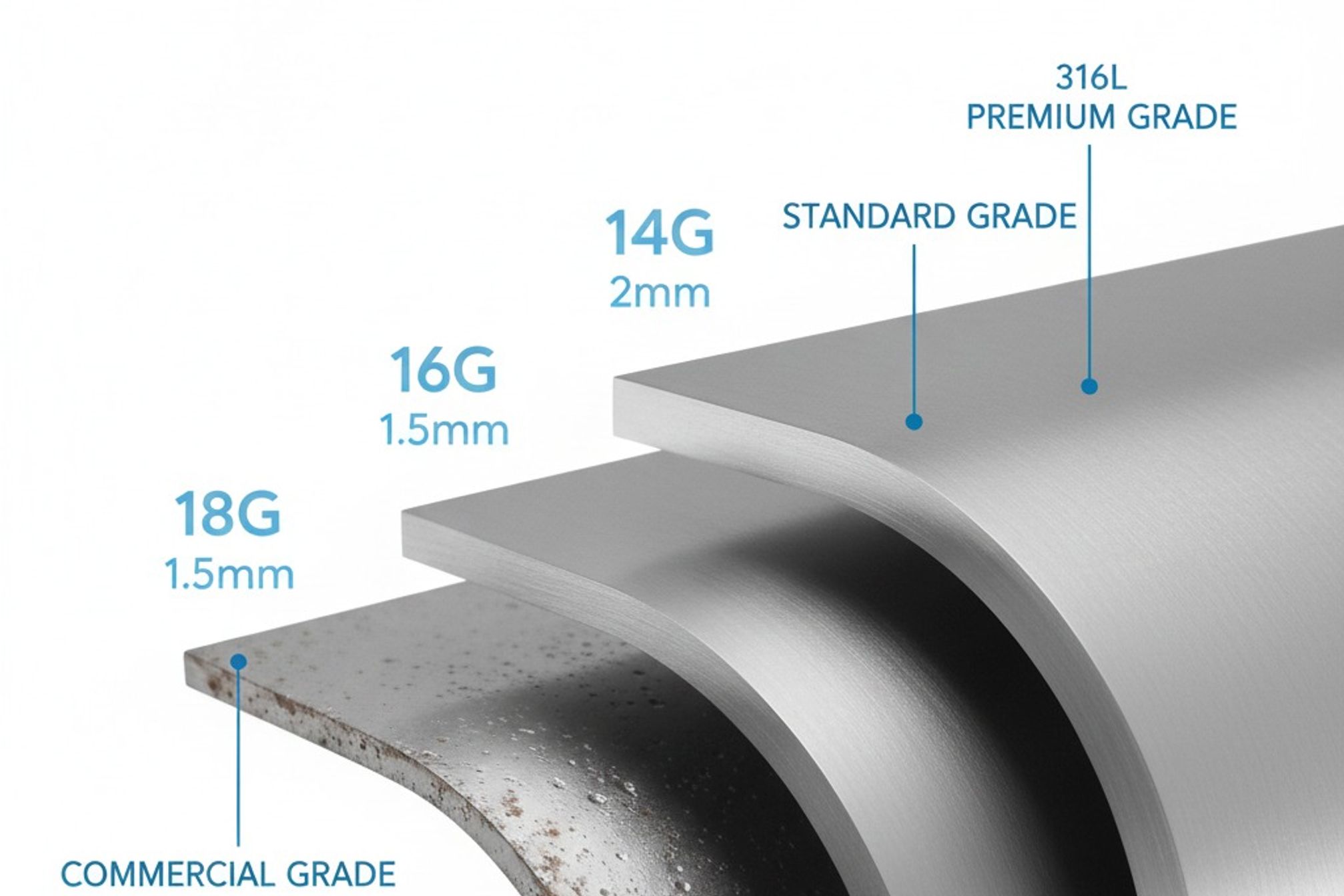

Steel tubing thickness gets measured in gauge numbers, and here's the confusing part: the numbers run backwards. Lower gauge number means thicker steel.

Most budget handrail kits use 18-gauge steel. That's about 0.048 inches thick—less than the thickness of a nickel. Some of the really cheap stuff is 20-gauge, which is thinner than a credit card.

I build with 14-gauge minimum, usually 12-gauge. That's 0.105 inches thick—more than twice the thickness of that budget kit material. For posts and structural elements, I often go to 11-gauge or even 10-gauge.

Doesn't sound like much difference, does it? Two nickels stacked versus one nickel?

But here's what actually happens.

The Physics of Failure

Thin-wall tubing flexes. Push on an 18-gauge handrail and you can feel it move. It bounces back when you let go, sure. But that flex is the steel telling you it's working too hard.

Every time that rail flexes, the welds get stressed. The mounting points get stressed. The powder coating starts to crack at the stress points. Do that enough times—and "enough times" isn't that many when you've got kids running up and down stairs or you're using the rail every day—and things start to fail.

I've seen rails where the tube actually bent away from the wall mounts. Seen welds crack. Seen the whole rail pull loose from the deck because the mounting bolts were working in holes that had enlarged from the constant flex.

Thick-wall tubing doesn't flex like that. When you grab a 12-gauge rail, it feels like grabbing a tree branch. Solid. Immovable. That's not just a nicer feeling—it's the rail doing its job without stressing the connections.

The Dent Factor

Here's something else: durability over time.

Utah winters are hard on exterior metalwork. You've got snow shovels, ice scrapers, maybe a snowblower that gets wheeled past your porch rail. You've got lawn equipment in summer. Kids with bikes. The vacuum cleaner bumping the interior stair rail when you're cleaning.

Thin tubing dents. I've seen handrails that looked like someone took a ball-peen hammer to them—all from normal household impacts that wouldn't even scratch heavier material.

A dent isn't just cosmetic. It's a weak point. It's where rust can start if the powder coating cracked. It's where the tube will want to fold if it gets hit again in the same spot.

Twelve-gauge steel? You'd have to really work at it to dent it. Normal household life doesn't even register.

The Code Minimum Trap

Building code requires handrails to withstand a 200-pound load. Here's what they don't tell you: that's the minimum for the rail not to catastrophically fail. It can flex like crazy, as long as it doesn't actually break.

The budget kit manufacturers build exactly to that minimum. Maybe a tiny bit over, just to be safe in testing. But they're optimizing for passing the test and hitting a price point, not for being a solid, reliable rail that'll still feel solid in ten years.

I build to feel bombproof because that's what a handrail should be. Not "technically meets code." Actually solid.

What You're Actually Paying For

When someone tells me my handrail quote is twice what they can get the materials for at Home Depot, they're not wrong about the price difference. But here's what that extra cost gets you:

Thicker material that won't flex when you need it. Welds that aren't stressed every time someone uses the rail. Mounting points that stay solid because they're not fighting constant movement. A rail that'll look the same and feel the same twenty years from now.

Also—and people don't always think about this—heavier gauge steel looks better. It has visual weight. Proportions look right. Skinny rails look flimsy because they are flimsy. Your eye knows it even if you can't articulate why.

When Thin Is Fine (Honestly)

I'll tell you straight: not every application needs 12-gauge steel.

Decorative elements? Infill panels that aren't structural? Interior situations where the rail truly is just a guide, not a safety feature? Sometimes thinner material is fine. I've used 16-gauge for decorative scrollwork that's backed by structural components.

But for the top rail—the part you actually grab—and for posts and structural members? I don't compromise. I've built enough railings and seen enough failures to know where you can save money and where you can't.

The Real Test

Here's how I know my work is solid: I install a rail, then I grab it and pull—hard. Put my weight on it. Shake it. If I can feel any flex or movement at all, something's wrong.

Try that with most prefab kits and you'll feel them move. They're designed to barely meet code, not to exceed it. They're engineered to a price point, not to a standard of quality.

The rails I build don't move. They feel like they're part of the structure—because with proper material thickness and solid mounting, they essentially are.

What Failure Looks Like

That guy who called me last week? His Home Depot rail had pulled two of the four deck mounting bolts completely loose. The flex had wallowed out the holes in the decking. Even if we'd tightened everything back up, it would've just failed again.

I ended up rebuilding the whole thing with proper materials. Cost him more than if he'd done it right the first time, plus he'd lived with a sketchy rail for two years.

He told me, "I wish I'd known this before." That's exactly why I'm writing this.

You can pay for proper material thickness once, or you can pay to replace a failed rail that never should've been installed. One of those options makes a lot more sense.